Turning inserts geometry

Turning geometries can be divided into three basic styles that are optimized for finishing, medium and roughing. The diagram shows the working area for each geometry, based on acceptable chip breaking, in relation to feed and depth of cut.Roughing

High depth of cut and feed rate combinations. Operations requiring the highest edge security.

Medium operations to light roughing. Wide range of depth of cut and feed rate combinations.

Operations at light depths of cut and low feed rates. Operations requiring low cutting forces.

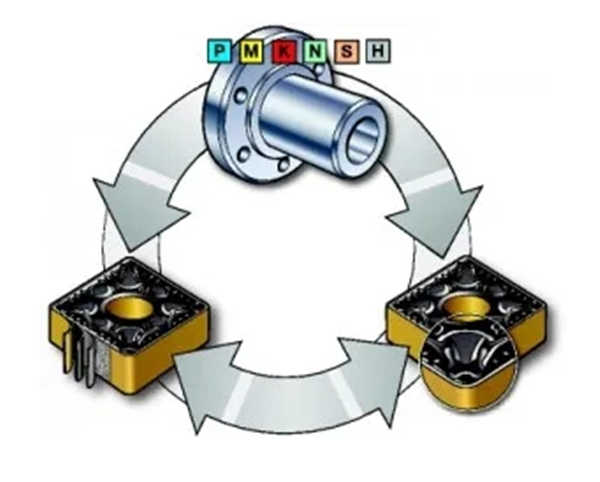

The inserts grade is primarily selected according to:

Component material ( ISO P, M, K, N, S, H )

Type of method ( finishing, medium, roughing )

Machining conditions ( good, average, difficult )

The inserts geometry and inserts grade complement each other. For example, the toughness of a grade can compensate for lack of strength in an insert geometry.

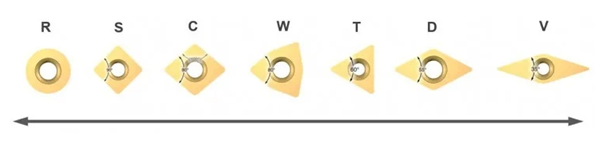

The inserts shape should be selected relative to the entering angle accessibility required of the tool. The largest possible nose angle should be selected to provide inserts strength and reliability. However, this has to be balanced against the variation of cuts that need to be performed.

A large nose angle is strong, but requires more machine power and has a higher tendency for vibration.

A small nose angle is weaker and has a small cutting edge engagement, both of which can make it more sensitive to the effects of heat.

(Large nose angle)

Stronger cutting edge

Higher feed rates

Increased cutting force

Increased vibration

Less vibration tendencies

(Small nose angle)

Increased accessibility

Decreased vibration

Decreased cutting force

Weaker cutting edge

Turning inserts size

Select inserts size depending on the application demands and the space for the cutting tool in the application.

With a larger inserts size, the stability is better. For heavy machining, the inserts size is normally above IC 25 mm (1 inch).

When finishing, the size can in many cases be reduced.

How to choose inserts size

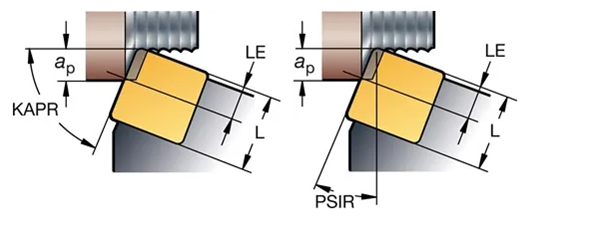

1.Determine the largest depth of cut, ap

2.Determine the necessary cutting length, LE, while also considering the entering (lead) angle of the tool holder, the depth of cut, ap, and the machine specification

3.Based on the necessary LE and ap, the correct cutting edge length, L, and IC for the insert can be selected

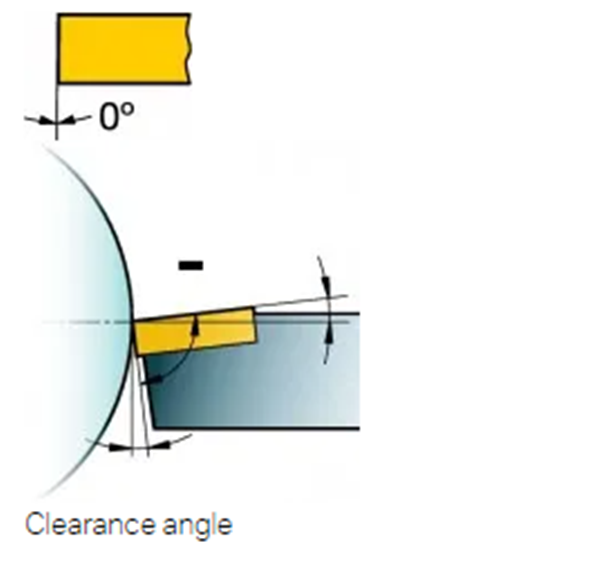

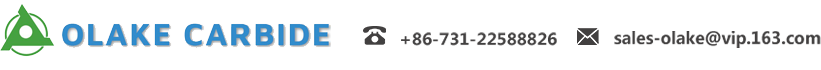

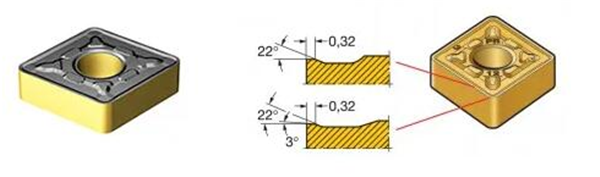

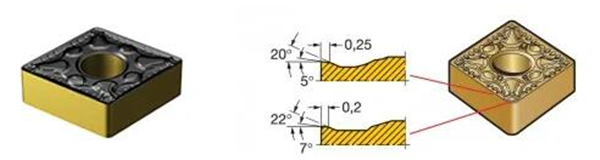

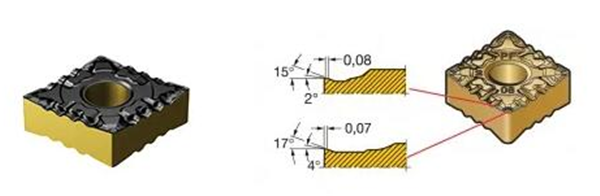

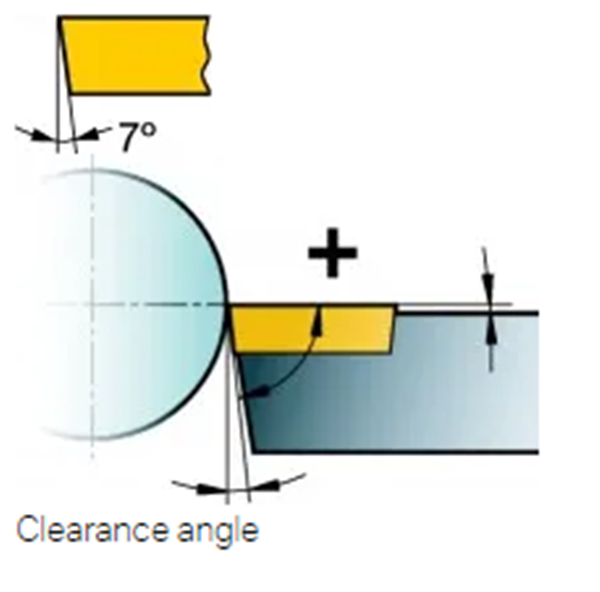

A negative insert has an angle of 90° (0° clearance angle), while a positive insert has an angle of less than 90° (for example, 7° clearance angle). The illustration of the negative style inserts, shows how the insert is assembled and tilted in the holder. Some characteristics of the two inserts types are listed below:

Positive turning insert

Single sided

Low cutting forces

Side clearance

First choice for internal turning and for external turning of slender components

Double and/or single sided

High edge strength

Zero clearance

First choice for external turning

Heavy cutting conditions