Made of 100% virgin carbide raw material, with good impact toughness, and high wear resistance, our carbide cold heading dies are used for manufacturing watch part, battery jar, steel ball, screw, bolt, etc.

Grades of cold heading dies

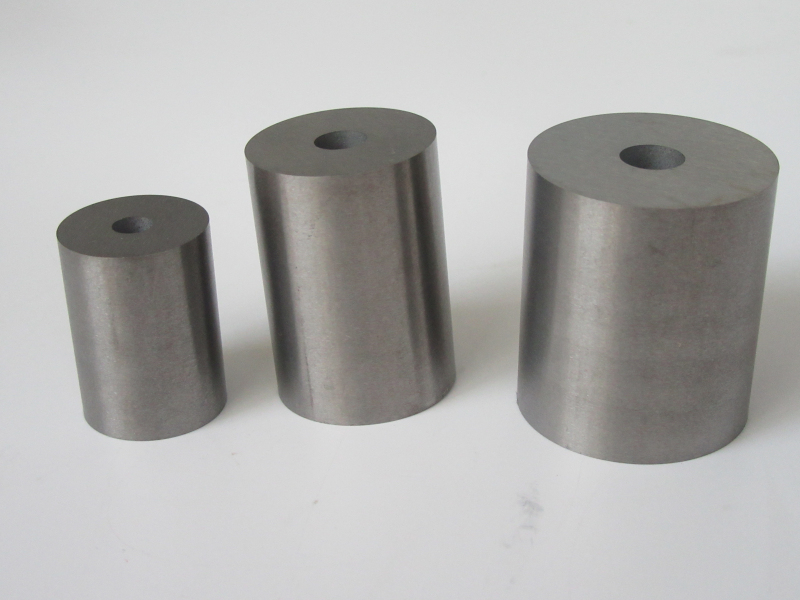

Carbide cold heading dies

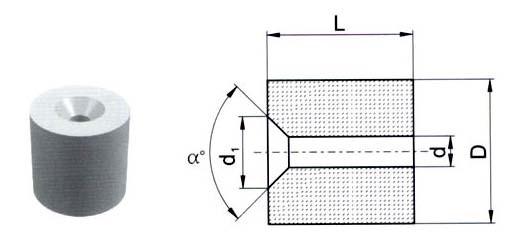

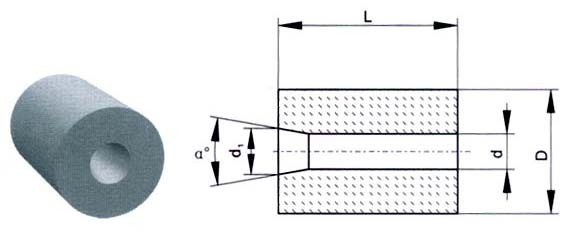

Die blanks with sink

| Type | Dimension | ||||

| d | D | L | d1 | α | |

| BC0281330 | 2.8 | 13 | 30 | 7 | 90 |

| BC0381630 | 3.8 | 16 | 30 | 8.5 | 90 |

| BC0381640 | 3.8 | 16 | 40 | 8.5 | 90 |

| BC0382250 | 3.8 | 22 | 50 | 8.5 | 90 |

| BC0461630 | 4.6 | 16 | 30 | 10.5 | 90 |

| BC0462250 | 4.6 | 22 | 50 | 10.5 | 90 |

| BC0643030 | 6.4 | 30 | 30 | 15 | 90 |

| BC0643055 | 6.4 | 30 | 55 | 15 | 90 |

| BC0823655 | 8.2 | 36 | 55 | 18 | 90 |

| BC1004055 | 10 | 40 | 55 | 22 | 90 |

| BC1184555 | 11.8 | 45 | 55 | 25 | 90 |

| BC1386060 | 13.8 | 60 | 60 | 29 | 90 |

Tolerances of the inner diameter(d) of the blanks as per table below(mm)

| Nominal inner dia. | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤6 | 0-0.45 | 0-0.55 | 0-0.65 | - |

| >6-10 | 0-0.50 | 0-0.60 | 0-0.70 | 0-0.80 |

| >10-14 | 0-0.55 | 0-0.70 | 0-0.80 | 0-0.90 |

| >14-18 | 0-0.60 | 0-0.80 | 0-0.90 | 0-1.00 |

| >18-24 | 0-0.65 | 0-0.90 | 0-1.00 | 0-1.10 |

| >24 | 0-0.70 | 0-1.00 | 0-1.10 | 0-1.20 |

Tolerance of out diameter(D) as table below(mm)

| Nominal out diameters | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤14 |

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

| >18-24 |

+0.60 -0.40 |

+0.60 -0.40 |

+0.65 -0.45 |

+0.70 -0.45 |

| >24-30 |

+0.65 -0.45 |

+0.65 -0.45 |

+0.70 -0.50 |

+0.75 -0.50 |

| >30-45 |

+0.70 -0.50 |

+0.70 -0.50 |

+0.75 -0.60 |

+0.80 -0.60 |

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 | - |

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

Tolerance of blank height(H) as table below (mm)

| Nominal out diameters | Nominal diameters | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤14 |

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

|

>18-24 +0.60 +0.60 -0.40 -0.40 |

+0.65 +0.70 -0.45 -0.45 |

|||

|

>24-30 +0.65 +0.65 -0.45 -0.45 |

+0.70 +0.75 -0.50 -0.50 |

|||

|

>30-45 +0.70 +0.70 -0.50 -0.50 |

+0.75 +0.80 -0.60 -0.60 |

|||

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 | - |

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

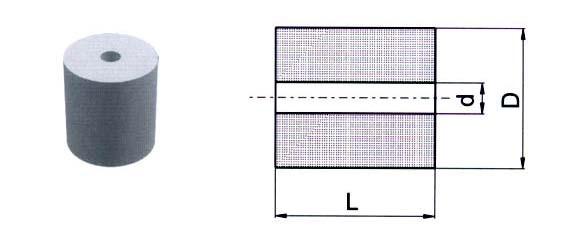

Heading die blanks for making standard bolts

| Type | Dimension |

Range of applications |

||

| d | D |

L Range of L |

||

| BDP00710- | 0.7 | 10 | 12.0~20.0 | M1 |

| BDP01010- | 1.0 | 10 | 12.0~20.0 | M1.5~M2 |

| BDP01013- | 1.0 | 13 | 15.4-40.0 | M1.5~M2 |

| BDP01213- | 1.2 | 13 | 15.4-40.0 | M1.5~M2 |

| BDP01510- | 1.5 | 10 | 12.0~25.0 | M2 |

| BDP01516- | 1.5 | 16 | 15.0-45.0 | M2 |

| BDP01813- | 1.8 | 13 | 12.0~35.0 | M2.5 |

| BDP01816- | 1.8 | 16 | 20.0-45.0 | M2.5 |

| BDP02113- | 2.1 | 13 | 15.0~30.0 | M3 |

| BDP02116- | 2.1 | 16 | 25.0-45.0 | M3 |

| BDP02316- | 2.3 | 16 | 15.0-45.0 | M3 |

| BDP02522- | 2.5 | 22 | 20.0-60.0 | M3 |

| BDP02813- | 2.8 | 13 | 15.0~30.0 | M4 |

| BDP02816- | 2.8 | 16 | 25.0-40.0 | M4 |

| BDP02818- | 2.8 | 18 | 20.0-50.0 | M4 |

| BDP02820- | 2.8 | 20 | 20.0-50.0 | M4 |

| BDP02822- | 2.8 | 22 | 20.0-60.0 | M4 |

| BDP02825- | 2.8 | 25 | 20.0-60.0 | M4 |

| BDP03216- | 3.2 | 16 | 15.0-45.0 | M4 |

| BDP03218- | 3.2 | 18 | 15.0-50.0 | M4 |

| BDP03616- | 3.6 | 16 | 20.0-50.0 | M5 |

| BDP03618- | 3.6 | 18 | 20.0-60.0 | M5 |

| BDP03822- | 3.8 | 22 | 20.0~40.0 | M5 |

| BDP03830- | 3.8 | 30 | 50.0~60.0 | M5 |

| BDP04218- | 4.2 | 18 | 20.0-60.0 | M5 |

| BDP04616- | 4.6 | 16 | 20.0~30.0 | M6 |

| BDP04622- | 4.6 | 22 | 35.0~60.0 | M6 |

| BDP05422- | 5.4 | 22 | 20.0~60.0 | M6 |

| BDP06422- | 6.4 | 22 | 20.0~60.0 | M8 |

| BDP06425- | 6.4 | 25 | 20.0~50.0 | M8 |

| BDP06430- | 6.4 | 30 | 25.0~60.0 | M8 |

| BDP07230- | 7.2 | 30 | 20.0~60.0 | M10 |

| BDP08230- | 8.2 | 30 | 20.0~60.0 | M10 |

| BDP08235- | 8.2 | 35 | 30.0~60.0 | M10 |

| BDP09230- | 9.2 | 30 | 20.0~60.0 | M12 |

| BDP10030- | 10.0 | 30 | 20.0~60.0 | M12 |

| BDP10035- | 10.0 | 35 | 30.0~60.0 | M12 |

| BDP11235- | 11.2 | 35 | 20.0~60.0 | M12 |

| BDP11240- | 11.2 | 40 | 20.0~60.0 | M12 |

| BDP11835- | 11.8 | 35 | 20.0~60.0 | M14 |

| BDP11840- | 11.8 | 40 | 25.0~30.0 | M14 |

| BDP13235- | 13.2 | 35 | 25.0~60.0 | M14 |

| BDP13240- | 13.2 | 40 | 25.0~50.0 | M14 |

| BDP13835- | 13.8 | 35 | 20.0~60.0 | M16 |

| BDP13840- | 13.8 | 40 | 25.0~35.0 | M16 |

| BDP14445- | 14.4 | 45 | 25.0~60.0 | M16 |

| BDP15445- | 15.4 | 45 | 30.0~50.0 | M18 |

| BDP16445- | 16.4 | 45 | 25.0~60.0 | M20 |

| BDP17445- | 17.4 | 45 | 25.0~60.0 | M20 |

| BDP19445- | 19.4 | 45 | 25.0~55.0 | M22 |

| BDP21050- | 21.0 | 50 | 25.0~55.0 | M24 |

| BDP24460- | 24.4 | 60 | 30.0~50.0 | M27 |

Tolerance of the inner diameter(d) of the blanks as per table below(mm)

| Nominal inner dia. | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤6 | 0-0.45 | 0-0.55 | 0-0.65 | - |

| >6-10 | 0-0.50 | 0-0.60 | 0-0.70 | 0-0.80 |

| >10-14 | 0-0.55 | 0-0.70 | 0-0.80 | 0-0.90 |

| >14-18 | 0-0.60 | 0-0.80 | 0-0.90 | 0-1.00 |

| >18-24 | 0-0.65 | 0-0.90 | 0-1.00 | 0-1.10 |

| >24 | 0-0.70 | 0-1.00 | 0-1.10 | 0-1.20 |

Tolerance of out diameter(D) as per table below(mm)

| Nominal out diameters | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

|

|

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

| >18-24 |

+0.60 -0.40 |

+0.60 -0.40 |

+0.65 -0.45 |

+0.70 -0.45 |

| >24-30 |

+0.65 -0.45 |

+0.65 -0.45 |

+0.70 -0.50 |

+0.75 -0.50 |

| >30-45 |

+0.70 -0.50 |

+0.70 -0.50 |

+0.75 -0.60 |

+0.80 -0.60 |

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 |

|

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

Tolerance of blank height(H) as per table below(mm)

| Nominal out diameters | Nominal diameters | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤14 |

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

| >18-24 |

+0.60 -0.40 |

+0.60 -0.40 |

+0.65 -0.45 |

+0.70 -0.45 |

| >24-30 |

+0.65 -0.45 |

+0.65 -0.45 |

+0.70 -0.50 |

+0.75 -0.50 |

| >30-45 |

+0.70 -0.50 |

+0.70 -0.50 |

+0.75 -0.60 |

+0.80 -0.60 |

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 | - |

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

The flatness as per table below

| Nominal length | ≤18 | >18-30 | >30-50 | >50 |

| Flatness ≤ | 0.30 | 0.35 | 0.40 | 0.55 |

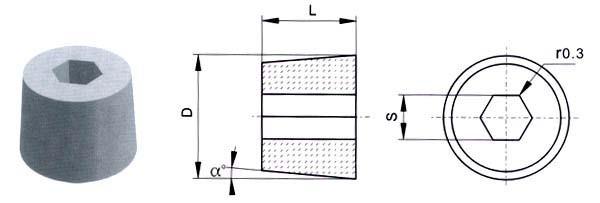

Heading die blanks for making hexagonal nuts

| Type | Dimension | Type | Dimension | ||||||

| S | D | Range of L | α。 | S | D | Range of L | α。 | ||

| BF02612- | 2.6 | 12 | 8-12 | - | BF12028- | 12.0 | 28 | 18 | 5-7 |

| BF03316- | 3.3 | 16 | 8-12 | - | BF12132- | 12.1 | 32 | 8-12 | |

| BF03412- | 3.4 | 12 | 8-12 | - | BF12132- | 12.1 | 32 | 18-22 | |

| BF04316- | 4.3 | 16 | 8-12 | - | BF13236- | 13.2 | 36 | 20-24 | |

| BF04416- | 4.4 | 16 | 10-14 | - | BF13236- | 13.2 | 36 | 26-34 | |

| BF04816- | 4.8 | 16 | 12-16 | - | BF13728- | 13.7 | 28 | 12 | 5-7 |

| BF04820- | 4.8 | 20 | 12-16 | - | BF14036- | 14.0 | 36 | 25 | 5-7 |

| BF06120- | 6.1 | 20 | 5 | 5-7 | BF15040- | 15.0 | 40 | 22-24 | |

| BF06320- | 6.3 | 20 | 14-18 | - | BF15040- | 15.0 | 40 | 26-34 | |

| BF06320- | 6.3 | 20 | 14-18 | - | BF16734- | 16.7 | 34 | 12 | 5-7 |

| BF07220- | 7.2 | 20 | 6 | 5-7 | BF17039- | 17.0 | 39 | 30 | 5-7 |

| BF07224- | 7.2 | 24 | 14-18 | - | BF17044- | 17.0 | 44 | 26-34 | |

| BF07328- | 7.3 | 28 | 14-18 | - | BF17936- | 17.9 | 36 | 13.5 | 5-7 |

| BF07328- | 7.3 | 28 | 18-22 | - | BF19044- | 19.0 | 44 | 18.5 | 5-7 |

| BF08920- | 8.9 | 20 | 7 | 5-7 | BF19952- | 19.9 | 52 | 34-38 | |

| BF09022- | 9.0 | 22 | 8 | 5-7 | BF20543- | 20.5 | 43 | 16.5 | 5-7 |

| BF09126- | 9.1 | 26 | 16 | 5-7 | BF22458- | 22.4 | 58 | 20.5 | 5-7 |

| BF09230- | 9.2 | 30 | 14-18 | - | BF22858- | 22.8 | 58 | 36-44 | |

| BF09328- | 9.3 | 28 | 14-18 | - | BF22863- | 22.8 | 63 | 44.5 | 5-7 |

| BF09328- | 9.3 | 28 | 18-22 | - | BF22944- | 22.9 | 44 | 17.0 | 5-7 |

| BF11236- | 11.2 | 36 | 20-24 | - | BF28172- | 28.1 | 72 | 45-55 | |

| BF11236- | 11.2 | 36 | 26-34 | - | BF28759- | 28.7 | 59 | 24.0 | 5-7 |

| BF11732- | 11.7 | 32 | 19 | 5-7 |

|

||||

Tolerance of inner diameter(d) of the blanks as per table below(mm)

| Nominal inner dia. | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤6 | 0-0.45 | 0-0.55 | 0-0.65 | - |

| >6-10 | 0-0.50 | 0-0.60 | 0-0.70 | 0-0.80 |

| >10-14 | 0-0.55 | 0-0.70 | 0-0.80 | 0-0.90 |

| >14-18 | 0-0.60 | 0-0.80 | 0-0.90 | 0-1.00 |

| >18-24 | 0-0.65 | 0-0.90 | 0-1.00 | 0-1.10 |

| >24 | 0-0.70 | 0-1.00 | 0-1.10 | 0-1.20 |

Tolerance of out diameter(D) as per table below(mm)

| Nominal out diameters | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

|

|

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

| >18-24 |

+0.60 -0.40 |

+0.60 -0.40 |

+0.65 -0.45 |

+0.70 -0.45 |

| >24-30 |

+0.65 -0.45 |

+0.65 -0.45 |

+0.70 -0.50 |

+0.75 -0.50 |

|

>30-45 +0.70 +0.70 -0.50 -0.50 |

+0.75 +0.80 -0.60 -0.60 |

|||

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 |

|

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

Tolerance of blank height(H) as per table below(mm)

| Nominal out diameters | Nominal diameters | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤14 |

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

|

>18-24 +0.60 +0.60 -0.40 -0.40 |

+0.65 +0.70 -0.45 -0.45 |

|||

| >24-30 |

+0.65 -0.45 |

+0.65 -0.45 |

+0.70 -0.50 |

+0.75 -0.50 |

| >30-45 |

+0.70 -0.50 |

+0.70 -0.50 |

+0.75 -0.60 |

+0.80 -0.60 |

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 | - |

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

The flatness as per table below

| Nominal length | ≤18 | >18-30 | >30-50 | >50 |

| Flatness ≤ | 0.30 | 0.35 | 0.40 | 0.55 |

Punching die blanks for making steel balls

| Type | Dimension (mm) | ||||||

| d1 | D | H | d | h | r1 | r2 | |

| BG01812102 | 1.8 | 12.2 | 10.2 | 0.8 | 0.5 | 0.4 | 1.0 |

| BG02212102 | 2.2 | 12.2 | 10.2 | 0.8 | 0.7 | 0.4 | 1.0 |

| BG02612102 | 2.6 | 12.2 | 10.2 | 0.9 | 0.9 | 0.4 | 1.0 |

| BG03012102 | 3.0 | 12.2 | 10.2 | 0.9 | 1.2 | 0.4 | 1.0 |

| BG03412102 | 3.4 | 12.2 | 10.2 | 0.9 | 1.3 | 0.4 | 1.0 |

| BG02812102 | 3.8 | 12.2 | 10.2 | 0.9 | 1.5 | 0.4 | 1.0 |

| BG04212102 | 4.2 | 12.2 | 10.2 | 0.9 | 1.7 | 0.4 | 1.0 |

| BG04812102 | 4.8 | 12.2 | 10.2 | 0.9 | 2.0 | 0.4 | 1.0 |

| BG05215122 | 5.2 | 15.2 | 12.2 | 0.9 | 2.2 | 0.6 | 1.5 |

| BG05615122 | 5.6 | 15.2 | 12.2 | 1.3 | 2.3 | 0.6 | 1.5 |

| BG06015122 | 6.0 | 15.2 | 12.2 | 1.3 | 2.5 | 0.6 | 1.5 |

| BG06515122 | 6.5 | 15.2 | 12.2 | 1.3 | 2.8 | 0.6 | 1.5 |

| BG06820152 | 6.8 | 20.2 | 15.2 | 1.3 | 2.8 | 0.6 | 1.5 |

| BG07320152 | 7.3 | 20.2 | 15.2 | 1.8 | 3.1 | 0.6 | 1.5 |

| BG08120152 | 8.1 | 20.2 | 15.2 | 1.8 | 3.5 | 0.6 | 1.5 |

| BG08620152 | 8.6 | 20.2 | 15.2 | 1.8 | 3.8 | 0.6 | 1.5 |

| BG09625202 | 9.6 | 25.3 | 20.2 | 2.3 | 4.2 | 0.8 | 2.0 |

| BG10225202 | 10.2 | 25.3 | 20.2 | 2.3 | 4.6 | 0.8 | 2.0 |

| BG10525202 | 10.5 | 25.3 | 20.2 | 2.3 | 5.0 | 0.8 | 2.0 |

| BG11225202 | 11.2 | 25.3 | 20.2 | 2.3 | 5.0 | 0.8 | 2.0 |

| BG11630202 | 11.6 | 30.3 | 20.2 | 2.3 | 5.0 | 0.8 | 2.0 |

| BG12030202 | 12.0 | 30.3 | 20.2 | 2.8 | 5.4 | 0.8 | 2.0 |

| BG12430202 | 12.4 | 30.3 | 20.2 | 2.8 | 5.6 | 0.8 | 2.0 |

| BG12830202 | 12.8 | 30.3 | 20.2 | 2.8 | 5.8 | 0.8 | 2.0 |

| BG13730202 | 13.7 | 30.3 | 20.2 | 2.8 | 6.2 | 0.8 | 2.0 |

| BG14030202 | 14.0 | 30.3 | 20.2 | 2.8 | 6.2 | 0.8 | 2.0 |

| BG14530202 | 14.5 | 30.3 | 20.2 | 3.3 | 6.6 | 0.8 | 2.0 |

| BG15335252 | 15.3 | 35.4 | 25.2 | 3.3 | 7.0 | 0.8 | 2.0 |

| BG16035252 | 16.0 | 35.4 | 25.2 | 3.3 | 7.3 | 0.8 | 2.0 |

| BG16835252 | 16.8 | 35.4 | 25.2 | 3.3 | 7.7 | 0.8 | 2.0 |

| BG17235252 | 17.2 | 35.4 | 25.2 | 3.8 | 7.7 | 0.8 | 2.0 |

| BG17640252 | 17.6 | 40.4 | 25.2 | 3.8 | 8.0 | 0.8 | 2.0 |

| BG18440252 | 18.4 | 40.4 | 25.2 | 3.8 | 8.3 | 0.8 | 2.0 |

| BG19240252 | 19.2 | 40.4 | 25.2 | 3.8 | 8.7 | 0.8 | 2.0 |

| BG20045302 | 20.0 | 45.4 | 30.2 | 3.8 | 9.1 | 1.0 | 2.5 |

| BG20845302 | 20.8 | 45.4 | 30.2 | 3.8 | 9.5 | 1.0 | 2.5 |

| BG21645302 | 21.6 | 45.4 | 30.2 | 3.8 | 9.8 | 1.0 | 2.5 |

| BG22445302 | 22.4 | 45.4 | 30.2 | 3.8 | 10.2 | 1.0 | 2.5 |

| BG23250302 | 23.2 | 50.4 | 30.2 | 4.3 | 10.6 | 1.0 | 2.5 |

| BG24050302 | 24.0 | 50.4 | 30.2 | 4.3 | 11.0 | 1.0 | 2.5 |

| BG24850302 | 24.8 | 50.4 | 30.2 | 4.3 | 11.4 | 1.0 | 2.5 |

| BG25550302 | 25.5 | 50.4 | 30.2 | 4.3 | 11.8 | 1.0 | 2.5 |

Tolerance of outer diameter (D) and height (H) as per table below(mm)

| Nominal inner dia. | Allowed tolerance |

| Normal class | |

| ≤14 | ±0.35 |

| >14-18 | ±0.40 |

| >18-25 | ±0.45 |

| >25-30 | ±0.50 |

| >30-40 | ±0.60 |

| >40-50 | ±0.65 |

| >50-60 | ±0.70 |

Tolerance of inner diameter (d) as per the table below (mm)

| Inner diameter | Allowed tolerance |

| Normal class | |

| d1 |

+0.40 -0.10 |

Die blanks for reducing diameter of nuts

| Type | Dimension | Type | Dimension | ||||||||

| d | D | Range of L | d1 | α。 | d | D | Range of L | d1 | α。 | ||

| BS02114- | 2.1 | 14 | 15-30 | 2.5 | 20 | BS08430- | 8.4 | 30 | 25-54 | 9.3 | 20 |

| BS02116- | 2.1 | 16 | 15-30 | 2.5 | 20 | BS10030- | 10.0 | 30 | 14-20 | 11.4 | 20 |

| BS03114- | 3.1 | 14 | 15-30 | 3.5 | 20 | BS10228- | 10.2 | 28 | 25-54 | 11.4 | 20 |

| BS03116- | 3.1 | 16 | 15-30 | 3.5 | 20 | BS10230- | 10.2 | 30 | 25-54 | 11.4 | 20 |

| BS03914- | 3.9 | 14 | 15-35 | 4.5 | 20 | BS11940- | 11.9 | 40 | 30-40 | 13.2 | 20 |

| BS03916- | 3.9 | 16 | 15-35 | 4.5 | 20 | BS12040- | 12.0 | 40 | 14-20 | 13.4 | 20 |

| BS04516- | 4.5 | 16 | 10-20 | 5.9 | 20 | BS14040- | 14.0 | 40 | 14-40 | 15.4 | 20 |

| BS04716- | 4.7 | 16 | 15-35 | 5.4 | 20 | BS17545- | 17.5 | 45 | 20-54 | 19.3 | 20 |

| BS04718- | 4.7 | 18 | 20-35 | 5.4 | 20 | BS19545- | 19.5 | 45 | 20-30 | 21.25 | 20 |

| BS06520- | 6.5 | 20 | 20-42 | 7.2 | 20 | BS21050- | 21.0 | 50 | 20-30 | 22.75 | 20 |

| BS06522- | 6.5 | 22 | 10-42 | 7.9 | 20 | BS24060- | 24.0 | 60 | 25-30 | 25.75 | 20 |

| BS08030- | 8.0 | 30 | 10-20 | 9.4 | 20 | BS26560- | 26.5 | 60 | 25-30 | 28.63 | 12 |

| BS08426- | 8.4 | 26 | 25-54 | 9.3 | 20 | BS32070- | 32.0 | 70 | 25-30 | 34.13 | 12 |

Tolerance of inner diameter(d) of the blanks as per table below (mm)

| Nominal inner dia. | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤6 | 0-0.45 | 0-0.55 | 0-0.65 | - |

| >6-10 | 0-0.50 | 0-0.60 | 0-0.70 | 0-0.80 |

| >10-14 | 0-0.55 | 0-0.70 | 0-0.80 | 0-0.90 |

| >14-18 | 0-0.60 | 0-0.80 | 0-0.90 | 0-1.00 |

| >18-24 | 0-0.65 | 0-0.90 | 0-1.00 | 0-1.10 |

| >24 | 0-0.70 | 0-1.00 | 0-1.10 | 0-1.20 |

Tolerance of out diameter(D) as per table below (mm)

| Nominal out diameters | Nominal length | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤14 |

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

| >18-24 |

+0.60 -0.40 |

+0.60 -0.40 |

+0.65 -0.45 |

+0.70 -0.45 |

| >24-30 |

+0.65 -0.45 |

+0.65 -0.45 |

+0.70 -0.50 |

+0.75 -0.50 |

| >30-45 |

+0.70 -0.50 |

+0.70 -0.50 |

+0.75 -0.60 |

+0.80 -0.60 |

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 | - |

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

Tolerance of blank height(H) as per table below (mm)

| Nominal out diameters | Nominal diameters | |||

| ≤18 | >18-30 | >30-50 | >50 | |

| ≤14 |

+0.50 -0.40 |

+0.50 -0.40 |

+0.60 -0.40 |

+0.65 -0.40 |

| >14-18 |

+0.55 -0.40 |

+0.55 -0.40 |

+0.60 -0.45 |

+0.65 -0.45 |

|

>18-24 +0.60 +0.60 -0.40 -0.40 |

+0.65 +0.70 -0.45 -0.45 |

|||

|

>24-30 +0.65 +0.65 -0.45 -0.45 |

+0.70 +0.75 -0.50 -0.50 |

|||

|

>30-45 +0.70 +0.70 -0.50 -0.50 |

+0.75 +0.80 -0.60 -0.60 |

|||

| >44-55 |

+0.75 -0.55 |

+0.80 -0.60 |

+0.85 -0.65 |

+0.80 -0.65 |

| >55 | - |

+0.90 -0.70 |

+0.95 -0.75 |

+1.00 -0.80 |

The flatness as per table below

| Nominal length | ≤18 | >18-30 | >30-50 | >50 |

| Flatness ≤ | 0.30 | 0.35 | 0.40 | 0.55 |

The flatness as per table below

| Type | Dimension | |||

| d | D | H | α° | |

| BR0902022 | 9.0 | 20 | 22 | 1° 30′ |

| BR0942022 | 9.4 | 20 | 22 | 1° 30′ |

| BR1042120 | 10.4 | 21 | 20 | 1° 30′ |

| BR1222520 | 12.2 | 25 | 20 | 1° 30′ |

| BR1253022 | 12.5 | 30 | 22 | 1° 30′ |

| BR1302520 | 13.0 | 25 | 20 | 1° 30′ |

| BR1303022 | 13.0 | 30 | 22 | 1° 30′ |

| BR1883622 | 18.8 | 36 | 22 | 1° 30′ |

| BR1923622 | 19.2 | 36 | 22 | 1° 30′ |

| BR1943220 | 19.4 | 32 | 20 | 1° 30′ |

| BR2204022 | 22.0 | 40 | 22 | 1° 30′ |

| BR2253820 | 22.5 | 38 | 20 | 1° 30′ |

| BR2254022 | 22.5 | 40 | 22 | 1° 30′ |

| BR2354022 | 23.5 | 40 | 22 | 1° 30′ |

| BR2393820 | 23.9 | 38 | 20 | 1° 30′ |

| BR2424022 | 24.2 | 40 | 22 | 1° 30′ |

| BR2884720 | 28.8 | 47 | 20 | 1° 30′ |

| BR3084720 | 30.8 | 47 | 20 | 1° 30′ |

| BR3124622 | 31.2 | 46 | 22 | 1° 30′ |

| BR3184720 | 31.8 | 47 | 20 | 1° 30′ |

Tolerance of punching dies for batteries as per table below (mm)

| Allowed tolerances | |||

| D | d | H | |

| ±0.6 | 8-24 | 0 /-0.8 | ±0.5 |

| >24-48 | 0 /-1.0 | ||

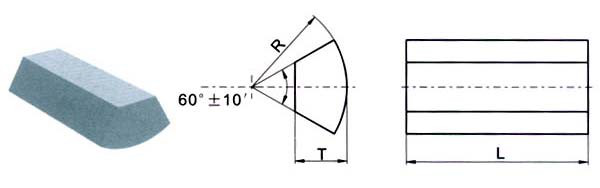

Combination die blanks for making hexagonal nuts

| Type | Dimension (mm) | Type | Dimension (mm) | ||||

| R | T | L | R | T | L | ||

| BP1100621 | 11.0 | 6 | 21 | BP2501432 | 25.0 | 14.0 | 32 |

| BP1100721 | 11.0 | 7 | 21 | BP2601223 | 26.0 | 12.5 | 23 |

| BP1300621 | 13.0 | 6.5 | 21 | BP2601237 | 26.0 | 12.0 | 37 |

| BP1500820 | 15.0 | 8 | 20 | BP2751436 | 27.5 | 14.0 | 36 |

| BP1601220 | 16.0 | 12 | 20 | BP2801123 | 28.0 | 11.0 | 23 |

| BP1800921 | 18.0 | 9 | 21 | BP2801323 | 28.0 | 13.0 | 23 |

| BP1801021 | 18.0 | 10 | 21 | BP2801143 | 28.0 | 11.0 | 43 |

| BP1800929 | 18.0 | 9 | 29 | BP2801343 | 28.0 | 13.0 | 43 |

| BP1801029 | 18.0 | 10 | 29 | BP2901835 | 29.0 | 18.0 | 35 |

| BP2001028 | 20.0 | 10.5 | 28 | BP3001442 | 30.0 | 14.0 | 42 |

| BP2001128 | 20.0 | 11.5 | 28 | BP3001542 | 30.0 | 15.0 | 42 |

| BP2251328 | 22.5 | 13.0 | 28 | BP3101347 | 31.0 | 13.0 | 47 |

| BP2251428 | 22.5 | 14.0 | 28 | BP3251446 | 32.5 | 14.5 | 46 |

| BP2301121 | 23.0 | 11.0 | 21 | BP3301226 | 33.0 | 12.5 | 26 |

| BP2301221 | 23.0 | 12.5 | 21 | BP3301251 | 33.0 | 12.5 | 51 |

| BP2301133 | 23.0 | 11.0 | 33 | BP3601326 | 36.0 | 13.0 | 26 |

| BP2301233 | 23.0 | 12.5 | 33 | BP3601356 | 36.0 | 13.0 | 56 |

| BP2501332 | 25.0 | 13.0 | 32 |

|

|||

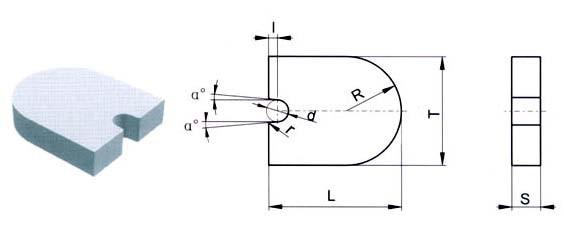

Blanks for cutting materials

| Type | Dimension (mm) | |||||||

| d | T | L | S | I | R | α° | r | |

| HQ0201012 | 2 | 10 | 12 | 1 | - | 5 | - | - |

| HQ0341616 | 3.4 | 16 | 16 | 2.5 | - | 8 | - | - |

| HQ0461616 | 4.6 | 16 | 16 | 4 | - | 8 | - | - |

| HQ0541616 | 5.4 | 16 | 16 | 5 | - | 8 | - | - |

| HQ0641012 | 6.4 | 10 | 12 | 2 | - | 5 | - | - |

| HQ0641616 | 6.4 | 16 | 16 | 5 | - | 8 | - | - |

| HQ0402525 | 4 | 25 | 25 | 3 | 5 | 12.5 | 5 | - |

| HQ0842222 | 8.4 | 22 | 22 | 5.5 | - | 11 | - | - |

| HQ0942222 | 9.4 | 22 | 22 | 8 | - | 11 | - | - |

| HQ0802525 | 8 | 25 | 25 | 4.5 | 5 | 12.5 | 5 | - |

| HQ0803030 | 8 | 30 | 30 | 6 | 5 | 15 | 5 | 0.5 |

| HQ1003030 | 10 | 30 | 30 | 10 | 3 | 15 | 6 | - |

| HQ1403635 | 14 | 36 | 35 | 13 | 3 | 18 | 6 | - |

Allowable tolerance of L(length), T(width) and S(thickness) of tips are listed in the table below (mm)

| Basic dimensions | Tolerance | Basic dimensions | Tolerance |

| ≤6 | ±0.2 | >25~40 | ±0.6 |

| >6~12 | ±0.3 | >40~55 | ±0.7 |

| >12~25 | ±0.4 |

|

Allowable tolerances of the flatness are listed in the table below (mm)

| Basic dimensions | ≤8 | >18~30 | >30 |

| Tolerance | 0.15 | 0.2 | 0.25 |